Innovation isn’t just a big idea on a whiteboard. For us, it often starts with a practical problem on the lab floor: something that needs fixing, improving, or reimagining so that our products and services are as safe, efficient, and future-ready as possible.

Here are two examples of how we’ve worked with local engineers to rethink standard equipment and make it work better for the challenges of next-generation treatments.

when standard equipment won’t cut it

When you work in the business of cellular therapies and cryogenic logistics serving NHS Trusts, research labs and clinics, you start to spot friction points: gaps between standard equipment and the demands of high-stakes biology.

At Biovault Technical, we view our role as extending beyond safe storage or processing, as defined by the HTA and JACIE frameworks. We have to make things work better, especially when “industry standard” isn’t quite enough. Below are two real, hands-on innovations we’ve developed with local engineering partners to make the biological materials logistics safer, more reliable, and more responsive to evolving therapies.

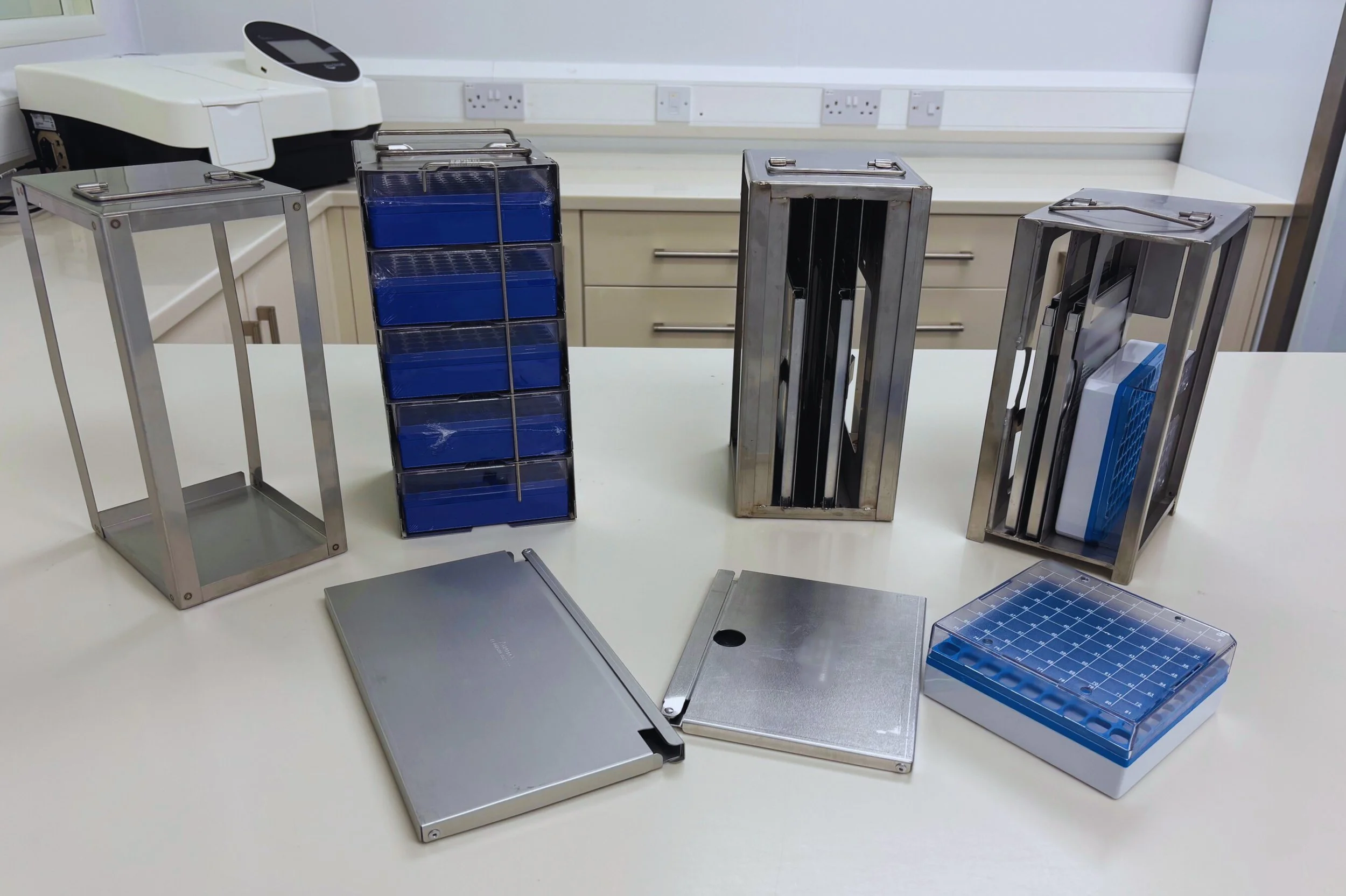

Industry standard MVE Cryoshipper and rack (left) and Biovault Technical enhanced cryoshipper racks (V1 second from right, V2 far right) for secure CAR-T transportation.

Innovation 1: Rethinking Cryoshipper Racks for CAR-T

From bubble wrap to a purpose-built rack system

When we first began handling CAR-T therapies and other IEC (immune effector cell) products under our WDA and cell therapy workflows, we saw a gap: the storage cassettes were unlike anything standard racks were designed for. They sat between the sizes of PBSC bags and cord blood units. If you tried to force-fit them into standard racks, you ran risks: movement, temperature variation, and damage.

Some facilities used bubble wrap or carved polystyrene, but we knew we could do better. If a therapy is life-changing, why wouldn’t you give it the best possible protection during transit?

“Why would you spend so much time and care processing a life-changing CAR-T product, then not make sure it has the best protection in transit?”

That’s when we teamed up with a local engineering firm and designed V1 of our IEC shipping rack. It was simple: a modified standard rack with a retaining bar to hold cassettes of different sizes securely in place. It worked. It wasn’t perfect, but it worked.

When the next wave of CAR-T development arrived, we knew we’d need something even better. Manufacturers were producing cassettes in all shapes and sizes, and we wanted to build a system that wasn’t just functional but adaptable. So came V2 of the rack:

Significantly lighter structure (so the rack itself doesn’t act as a heat sink)

Less bulk, less material, fewer cold bridges

Easier bag handling even while wearing Cryogloves

More compact and flexible for different shipper layouts

Better balance of rigidity vs insulation

In short, we turned a workaround into a purpose-built solution shaped by testing, feedback, and a commitment to continuous improvement.

Innovation 2: Making CRF Racks Safer and Smarter

Because no one wants to go fishing in liquid nitrogen

Controlled-rate freezers (CRFs) are crucial to cryopreservation of PBSCs, IECs, and other cellular products. But anyone who’s worked with CRFs knows the challenge: once the vapour fills the chamber, you can’t see the bottom. It’s not unusual for vials to fall off cryocanes. Far from what any research partner, healthcare professional or patient would hope for or expect when handling life‑saving cellular therapies. The operator then has to go fishing in the CRF for the vial, which, in Cryogloves with limited feel, is a mission in itself.

Our V1 rack redesign was a simple but effective fix. We cut and fitted the original rack inside a cage, added a bar to secure cryocanes, and built in a handle so the entire assembly could be lifted out of the freezer in one action. As a bonus, the cryocanes clipped neatly onto the handle - something we hadn’t planned, and was a benefit of working with an experienced engineering company who simply amended the design as it worked better.

When we expanded our fleet of CRFs, we asked ourselves the obvious question: stick with what worked, or take another step forward? Of course, we chose the second option.

V2 of the rack brought:

Smaller holding points to secure cassettes more tightly

Thinner mesh to allow better laminar flow of nitrogen

Thinner metal to reduce heat sink and lighten the load for operators

Racks and cassettes made from the same material for continuity

Another example of how a practical day-to-day problem led us to design something that works better — not just for us, but for the therapies and patients at the heart of it all.

Biovault Technical’s enhanced CRF racks. V1 on the left solved the problem, but V2’s finer mesh and lighter design enhanced functionality and operational expereince for a perfect solution to lost vials.

Why These Stories Matter to Trusts, Labs & Patients

Trust in capability: When you partner with Biovault (for processing, long-term storage, cold chain logistics, consultancy) you’re working with a team that doesn’t just store cells. We solve cell problems.

Incremental, pragmatic innovation: We don’t chase flashy concepts; we chase what works in the real world of vapour, Cryogloves, temperature margins, and tight timelines.

Regulation meets creativity: Every design is validated within HTA, MHRA, JACIE, GMP, GDP boundaries. Innovation does not compromise compliance — it reinforces it.

Built to evolve: As cellular therapies change: new cassette types, modified protocols, different packaging approaches, our tools are ready to shift too.

When organisations engage with us, they’re getting a partner who thinks under the hood. You’re not just outsourcing storage or distribution, you’re collaborating in a living, adapting system built for tomorrow’s therapies.